2005 BIGLIA B 301

2005 BIGLIA B 301

Contact us for price

Location:Urgnano, Italy

or

Call +39 035 – 0392235

Description

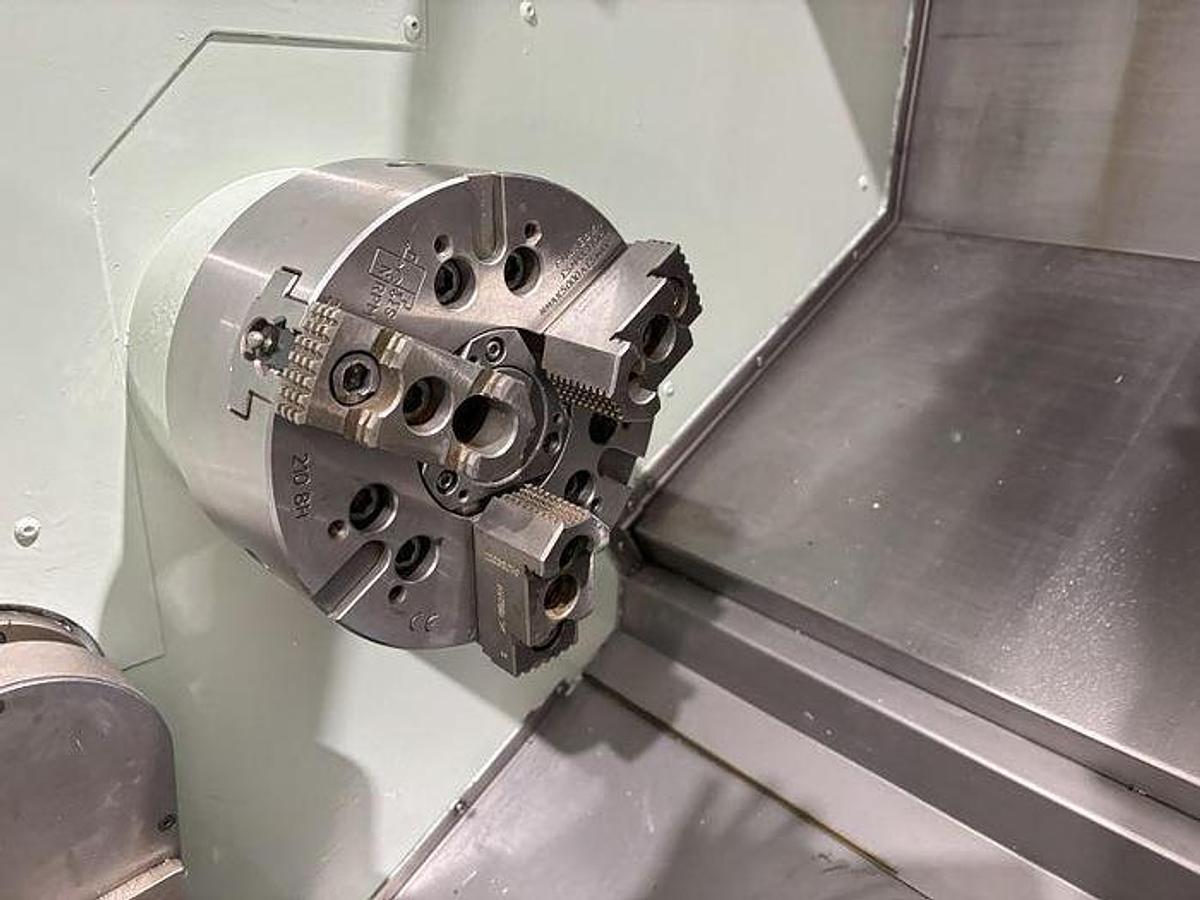

The 2005 Biglia B 301 CNC lathe is a used machine, designed to offer precision and reliability in the work of

turning. Equipped with a GE Fanuc Series 21i-TB numerical control, this model is ideal for machining on

bars with a maximum diameter of 42 mm and on reworked pieces up to 220 mm. The maximum workable length is 380 mm,

while the maximum rotating diameter reaches 400 mm.

The machine is equipped with a main spindle that offers a variable rotation range from 100 to 5000 rpm, with a

ASA 5" spindle nose and a 55mm spindle bore. The bi-directional turret features 12 tool positions,

supporting 20x20 mm external tool shanks and reamer up to 32 mm diameters. The setup includes a tailstock

hydraulic with automatic 100 mm stroke of the quill and manual positioning up to 380 mm.

The machine includes useful accessories such as an additional 7 bar high pressure coolant pump with filter

cartridge and a 210 mm self-centering chuck. With overall dimensions of 3500 x 1754 x 1935 mm and a weight of 3550 kg,

This machine represents a solid solution for advanced turning operations in industrial environments.

Specifications

| Manufacturer | BIGLIA |

| Model | B 301 |

| Year | 2005 |

| Condition | Used |

| Stock Number | 00040 |

| CNC: | GE Fanuc Series 21i-TB |

| Max. workable diameter from bar | 42 mm |

| Max. workable diameter from recovery | 220 mm |

| Max. workable length | 380 mm |

| Max. rotating diameter | mm 400 |

| MAIN SPINDLE: Variable rotation range | rpm 100-5000 |

| Spindle nose | ASA 5" |

| Spindle hole | mm 55 |

| Front bearing inner diameter | 90 mm |

| Motor power | Kw 11-15(50%) |

| TURRET: Number of positions | 12 |

| Guy | bidirectional |

| External tool stem | 20x20 mm |

| Reamer tool shank | mm ø25 ø32 |

| Rotation time (1 position) | sec. 0.15 |

| HYDRAULIC TAILSTOCK: | Automatic quill stroke 100 mm |

| Tip holder cone | CM. 4-5 |

| Manual positioning | 380 mm |

| "X" axis travel | mm 160(145+15) |

| "Z" axis travel | mm 380(360+20) |

| "B" axis travel | 440 mm |

| Overall dimensions with chip conveyor | mm 3500 x 1754 x 1935 h |

| Weight with chip conveyor | 3550 kg |

| ACCESSORIES INCLUDED | • N. 1 Additional PUMP for high pressure coolant (7 bar) complete with cartridge FILTER suitable for standard 4 bar and 7 bar pumps • PALETTE and CHUTE for unloading machined pieces up to a maximum length of 200 mm. • N. 5 fixed tool holders + 3 Extra • N. 1 Self-centering 210 |

| Weight with chip conveyor | 3550 kg |

| ACCESSORIES INCLUDED | • N. 1 Additional PUMP for high pressure coolant (7 bar) complete with cartridge FILTER suitable for standard 4 bar and 7 bar pumps • PALETTE and CHUTE for unloading machined pieces up to a maximum length of 200 mm. • N. 5 fixed tool holders + 3 Extra • N. 1 Self-centering 210 |

| Max. workable diameter from bar | 42 mm |

| Max. workable diameter from recovery | 220 mm |

| Max. workable length | 380 mm |

| Max. rotating diameter | mm 400 |

| MAIN SPINDLE: Variable rotation range | rpm 100-5000 |

| Spindle nose | ASA 5" |

| Spindle hole | mm 55 |

| Front bearing inner diameter | 90 mm |

| Motor power | Kw 11-15 (50%) |

| TURRET: Number of positions | 12 |

| Guy | bidirectional |

| External tool stem | 20x20 mm |

| Reamer tool shank | mm ø25 ø32 |

| Rotation time (1 position) | sec. 0.15 |

| HYDRAULIC TAILSTOCK: | Automatic quill stroke 100 mm |

| Tip holder cone | CM. 4-5 |

| Manual positioning | 380 mm |

| "X" axis travel | mm 160(145+15) |

| "Z" axis travel | mm 380(360+20) |

| Overall dimensions with chip conveyor | mm 3500 x 1754 x 1935 h |

| "B" axis travel | 440 mm |